Curved Aluminum Fin Facade for Mixed‑Use Podium

Project Details

Project snapshot

- Sector: High‑end residential and retail podium

- Scope: Design assist, engineering, fabrication, coating, logistics, on‑site advisory

- System: Open‑joint metal curtain wall with curved aluminum fins and integrated green columns

Overview

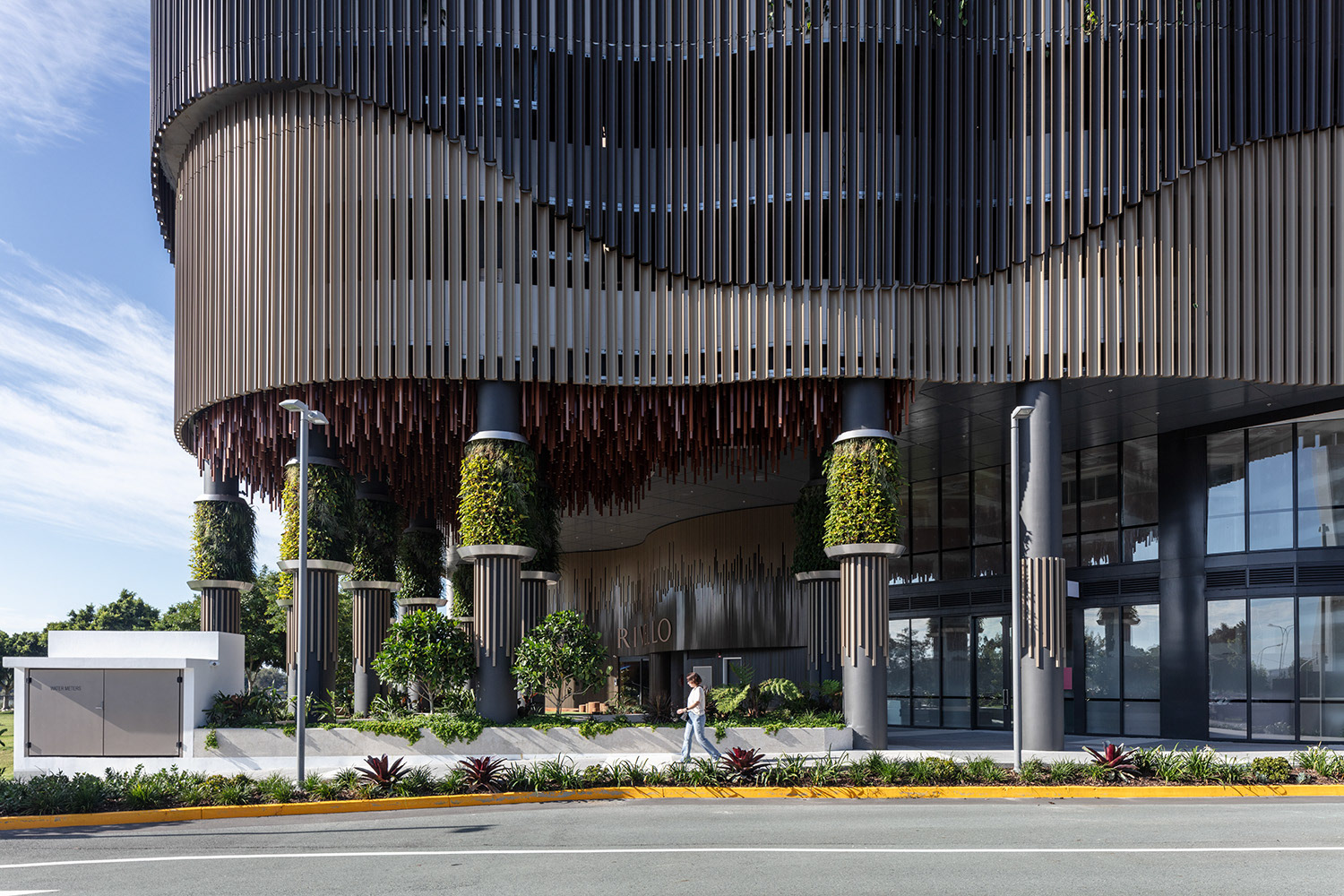

We manufactured the signature metal curtain wall for a new riverfront development. The façade combines flowing curves, vertical fins and shaded arcades to create a refined, durable landmark.

Our team delivered shop drawings, prototypes and full QC documentation. The result is a distinctive podium that enhances comfort and brand value from day one.

Design brief

The architect sought a sculptural screen that softens sun and frames the ground‑floor retail. It needed coastal‑grade durability and clean, concealed fixings.

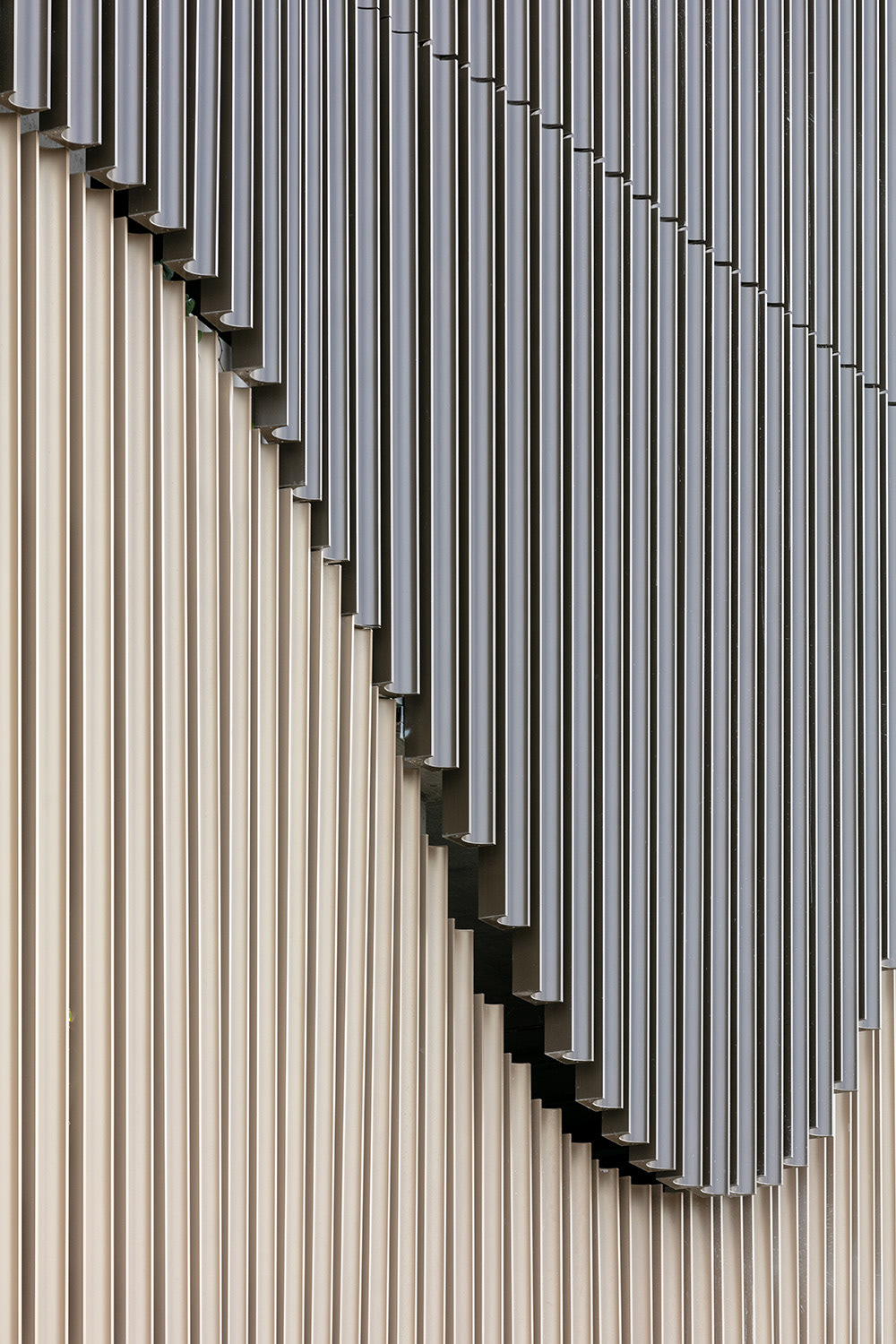

We proposed a parametric fin system with variable pitch and depth. This achieves the wave effect while keeping installation practical and repeatable.

Facade system

The podium uses an open‑joint rainscreen with extruded fins mounted on hidden rails. Fin spacing varies to create a gentle gradient and controlled transparency.

Curved corners are formed with segmented radii, ensuring precise alignment. Shadow lines remain continuous across columns and soffits.

Materials and finishes

Primary components are marine‑grade aluminum alloy with PVDF and super‑durable powder coatings. Colors blend champagne, bronze and graphite for a timeless palette.

Exposed fasteners are A4/316 stainless steel. All interfaces use EPDM gaskets and thermal isolators to prevent bimetallic corrosion.

Engineering and tolerances

Support rails are laser‑set with adjustable brackets to absorb building tolerances. Expansion joints are concealed within rhythm breaks and shadow reveals.

The system is engineered for high wind and driving rain typical of subtropical waterfront sites. Panels are serviceable from the underside to simplify maintenance.

Sustainability

Deep vertical fins cut solar gain and glare while preserving outward views. The shaded arcade cools the public realm and reduces mechanical load.

Greened columns and planters support biodiversity and improve microclimate. Coatings are low‑VOC and selected for long re‑coat cycles.

Manufacturing and QA

We produced a full‑scale mock‑up to verify color, gloss and fixings. Every fin is laser‑numbered, packed by elevation and tracked through our inspection test plan.

Edges are deburred and sealed to resist salt‑spray exposure. Export crates were designed for safe, sequence‑based unloading on site.

Installation

Pre‑assembled fin cassettes sped up crane time and minimized street closures. Templated brackets and datum lines helped local installers achieve tight joins.

The podium was enclosed on schedule, allowing landscape and fit‑out to proceed early. Site adjustments were minimal due to accurate fabrication.

Performance benefits

- Reduced heat gain and softer daylight for ground‑floor spaces.

- Robust coastal protection with marine‑grade coatings and stainless fixings.

- Quick, safe installation via modular cassettes and clear part numbering.

- A recognizable façade that elevates leasing and visitor appeal.

Client feedback

Our client reported strong public response and smooth handover. The curtain wall met the design intent and maintenance targets from the first season.

Optimization suggestions

- Add bird‑safe frit or micro‑texture to glass behind open fins where needed.

- Integrate discreet LED grazers to highlight the wave geometry at night.

- Consider PV cladding on roof parapets and smart irrigation for green columns.

- Plan a 5‑year wash and coating audit to extend service life in marine air.

Outcome

This façade demonstrates how engineered metalwork can deliver artful form and reliable function. It stands up to coastal weather while welcoming people at street level.

Call to action

Planning a custom metal curtain wall or fin façade? Our engineering team can provide budgeting, samples and a clear delivery program for your schedule.